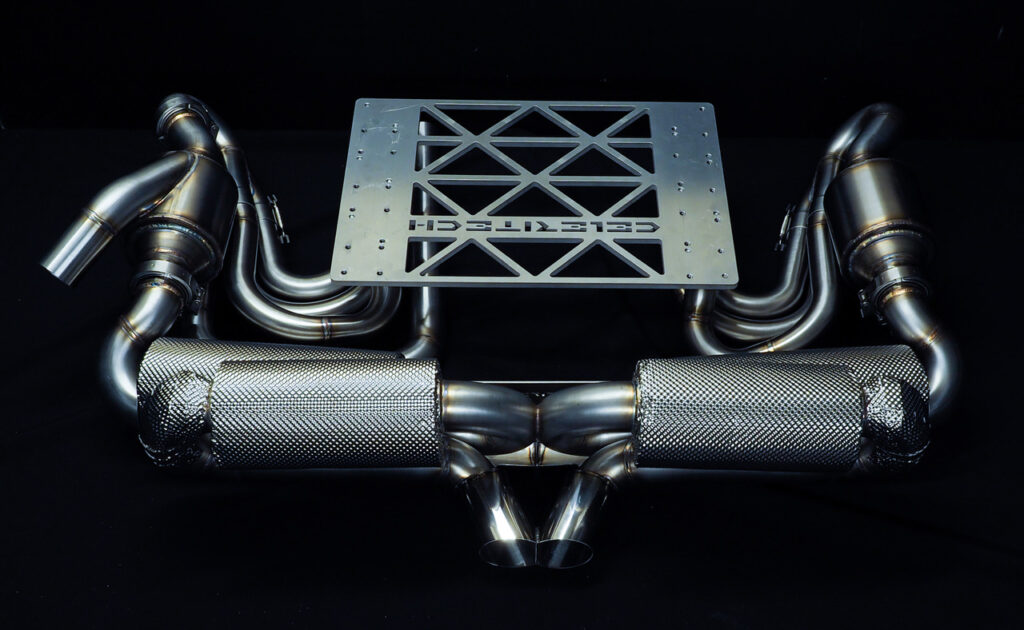

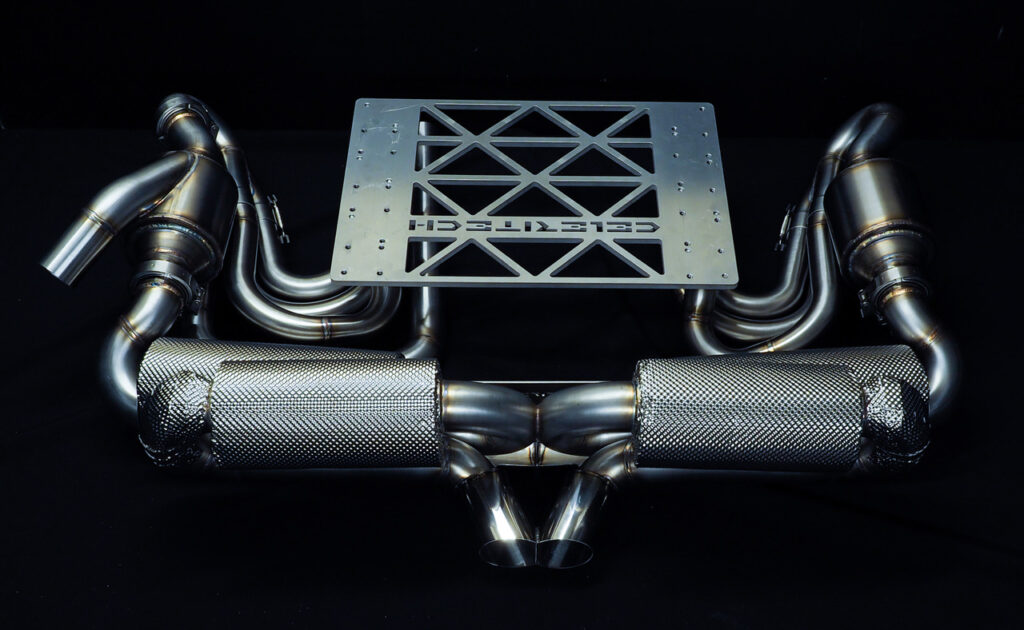

Technology has advanced almost everything we do at KALMAR Automotive so why should an exhaust system be any different? Created in partnership with Dutch specialist Celeritech, the KALMAR Automotive Exhaust System is both a shining example of how modern computer design has helped us to build an out-of-this-world system, and a work of art in its own right – fit for a gallery.

The unique Celeritech process – called photogrammetry – begins with an extensive photoshoot. Each aspect of the car’s existing exhaust system, engine bay and underside are painstakingly captured using a close-range 3D scanner to create a virtual 3D model needed to design the system. From this intricate scan comes the construction of a bespoke 3D digital model, a framework from which work for the new system can truly begin using Celeritech’s own specialised design software – developed in-house. Attention to detail is key, no stone is left unturned in creating a virtual picture of the form the system will take, what it will ultimately look like and – most importantly – how it will function. In addition, this forensic analysis helps ensure the system has precise, true equal length headers, something Celeritech takes huge pride in and which delivers inherent performance advantages, as well as substantial sound benefits!

The team considers each aspect of the state-of-the-art CAD design before production. That means prior to fabrication, the KALMAR customer can completely tailor the system. A 3D render is shared with the customer so that any changes can be discussed and incorporated into the final form. The basis for the design of the KALMAR system was even more intensive. Built with a view to extracting optimum performance, the project called for a close collaboration between KALMAR, Celeritech and engine partner Lorrtec. Crucial aspects, such as the length and diameter of the primaries and secondaries were tested repeatedly, painstakingly checking the impact of each new adjustment to ensure it had the correct effect on the performance and power delivery of the engine. Here, Celeritech’s Tjabring Snel and Lorrtech’s Pierre Antoie Rampo harnessed their extensive experience of engine development and simulation work for professional motorsport applications, helping to strike what is a tricky balance between packaging, heat output, noise and desired performance outcome. You can see from our power graph that our goal was to create a drivable car with a wide power band and smooth idle, with the drive by wire system delivering power just like a modern car.

The fabrication process at Celeritech is as sophisticated as the design and development stages, working to the tight tolerances mapped out by the CAD design. It employs Celeritech’s own techniques and accurate CNC cutting via a special jig system, alongside TIG welding practices. Working with stainless steel and Inconel – a high tech material used in Formula One – the digital template comes to life, providing the precise number of degrees that the tubing sections need to twist relative to each other. Everything must be millimeter perfect. In fact, it’s checked with a laser system to support Celeritech’s own “perfect fit” guarantee. Heat protection comes in two forms, mechanically wrapped insulation and Ceracoat temperature treatments. The final product precisely replicates the virtual 3D design with true equal length becoming reality. Exactly what we wanted for KALMAR cars.

The completed KALMAR system is built from 304 grade stainless steel with a wall thickness of just 1.2mm (typically systems employ a less impressive 1.5mm wall), or as little as 0.7mm where Inconel is used, making it even lighter. Talking of weight, the Celeritech / KALMAR Automotive stainless steel system tips the scales at 27.7kgs (the original 993 system, as incomparable as it is in pretty much every way, weighs 38.6kgs). And the optional Inconel is even lighter still. Catalytic converters and a quartet of free-flowing silencers complete the recipe. Now, this feels like an opportune moment to mention sound! We’d be lying if we said we didn’t want an exhaust note to stir the soul, but this is another area where a compromise – this time between power and decibels – is often required. KALMAR Automotive demanded that its cars be homologated, but also nice to drive over longer distances, all without losing the soul of the Boxer six-cylinder, in this the team succeeded. Key factors such were the compression ratio and cam duration, with valve lift playing an equally important role in the eventual tune emitted from the rear. As space is tight on a Porsche 911 there was a need for an inventive approach in getting everything to fit. Our system’s true equal also lengths play an important role in producing the unique, melodic sound. Note that the sound from the system is well within the limits of road and track use, avoiding unwanted resonance with all its pulses arriving at the right intervals – largely created by its true equal length. It’s just like a perfectly tuned piano.

The team considers each aspect of the state-of-the-art CAD design before production. That means prior to fabrication, the KALMAR customer can completely tailor the system. A 3D render is shared with the customer so that any changes can be discussed and incorporated into the final form. The basis for the design of the KALMAR system was even more intensive. Built with a view to extracting optimum performance, the project called for a close collaboration between KALMAR, Celeritech and engine partner Lorrtec. Crucial aspects, such as the length and diameter of the primaries and secondaries were tested repeatedly, painstakingly checking the impact of each new adjustment to ensure it had the correct effect on the performance and power delivery of the engine. Here, Celeritech’s Tjabring Snel and Lorrtech’s Pierre Antoie Rampo harnessed their extensive experience of engine development and simulation work for professional motorsport applications, helping to strike what is a tricky balance between packaging, heat output, noise and desired performance outcome. You can see from our power graph that our goal was to create a drivable car with a wide power band and smooth idle, with the drive by wire system delivering power just like a modern car.

The fabrication process at Celeritech is as sophisticated as the design and development stages, working to the tight tolerances mapped out by the CAD design. It employs Celeritech’s own techniques and accurate CNC cutting via a special jig system, alongside TIG welding practices. Working with stainless steel and Inconel – a high tech material used in Formula One – the digital template comes to life, providing the precise number of degrees that the tubing sections need to twist relative to each other. Everything must be millimeter perfect. In fact, it’s checked with a laser system to support Celeritech’s own “perfect fit” guarantee. Heat protection comes in two forms, mechanically wrapped insulation and Ceracoat temperature treatments. The final product precisely replicates the virtual 3D design with true equal length becoming reality. Exactly what we wanted for KALMAR cars.

The completed KALMAR system is built from 304 grade stainless steel with a wall thickness of just 1.2mm (typically systems employ a less impressive 1.5mm wall), or as little as 0.7mm where Inconel is used, making it even lighter. Talking of weight, the Celeritech / KALMAR Automotive stainless steel system tips the scales at 27.7kgs (the original 993 system, as incomparable as it is in pretty much every way, weighs 38.6kgs). And the optional Inconel is even lighter still. Catalytic converters and a quartet of free-flowing silencers complete the recipe. Now, this feels like an opportune moment to mention sound! We’d be lying if we said we didn’t want an exhaust note to stir the soul, but this is another area where a compromise – this time between power and decibels – is often required. KALMAR Automotive demanded that its cars be homologated, but also nice to drive over longer distances, all without losing the soul of the Boxer six-cylinder, in this the team succeeded. Key factors such were the compression ratio and cam duration, with valve lift playing an equally important role in the eventual tune emitted from the rear. As space is tight on a Porsche 911 there was a need for an inventive approach in getting everything to fit. Our system’s true equal also lengths play an important role in producing the unique, melodic sound. Note that the sound from the system is well within the limits of road and track use, avoiding unwanted resonance with all its pulses arriving at the right intervals – largely created by its true equal length. It’s just like a perfectly tuned piano.

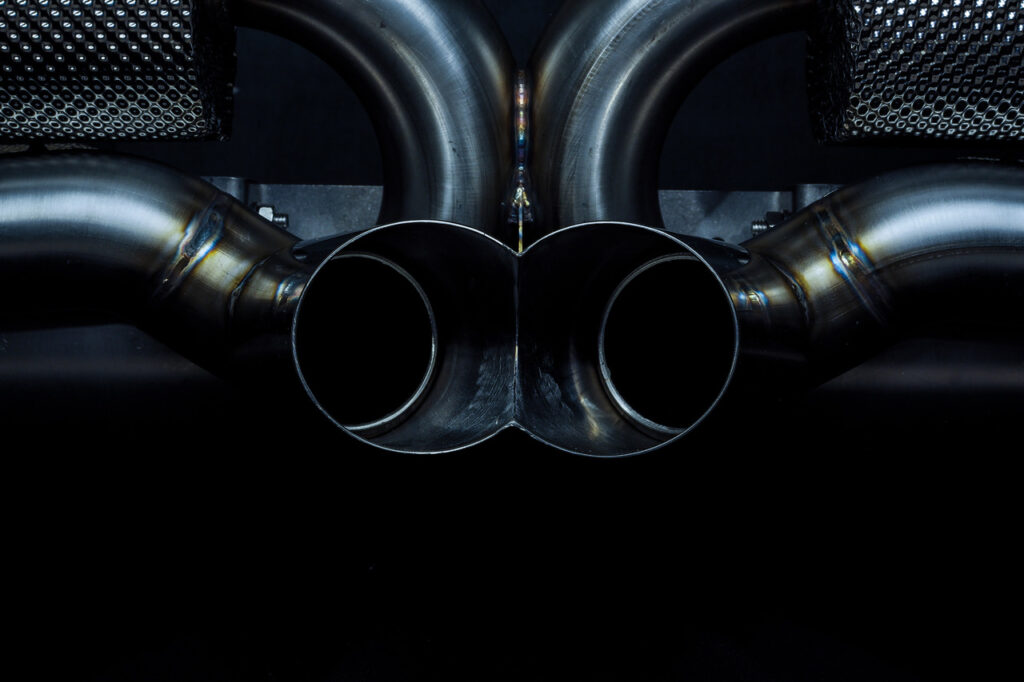

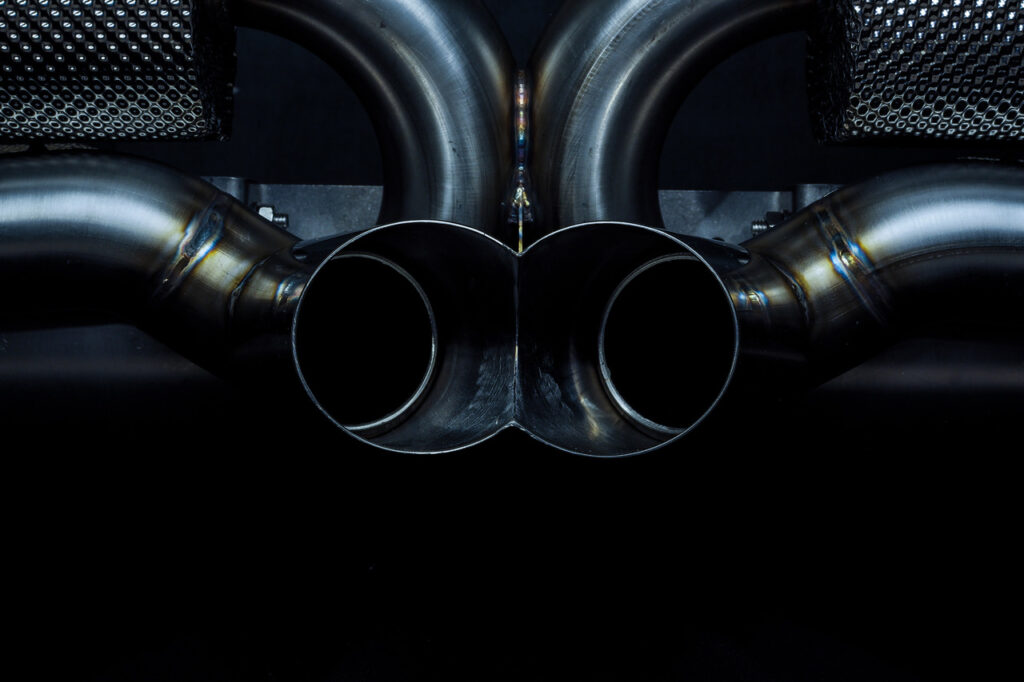

Finally, KALMAR customers can choose from three different tailpipe options for straight pipes, with a unique crossover infinity design being one of the highlights. The finishing touch is the Celeritech engraving, which marks out the KALMAR Automotive system as a beautiful, tight-fitting, high-performance exhaust system – something special created by passionate enthusiasts.

Finally, KALMAR customers can choose from three different tailpipe options for straight pipes, with a unique crossover infinity design being one of the highlights. The finishing touch is the Celeritech engraving, which marks out the KALMAR Automotive system as a beautiful, tight-fitting, high-performance exhaust system – something special created by passionate enthusiasts.

The team considers each aspect of the state-of-the-art CAD design before production. That means prior to fabrication, the KALMAR customer can completely tailor the system. A 3D render is shared with the customer so that any changes can be discussed and incorporated into the final form. The basis for the design of the KALMAR system was even more intensive. Built with a view to extracting optimum performance, the project called for a close collaboration between KALMAR, Celeritech and engine partner Lorrtec. Crucial aspects, such as the length and diameter of the primaries and secondaries were tested repeatedly, painstakingly checking the impact of each new adjustment to ensure it had the correct effect on the performance and power delivery of the engine. Here, Celeritech’s Tjabring Snel and Lorrtech’s Pierre Antoie Rampo harnessed their extensive experience of engine development and simulation work for professional motorsport applications, helping to strike what is a tricky balance between packaging, heat output, noise and desired performance outcome. You can see from our power graph that our goal was to create a drivable car with a wide power band and smooth idle, with the drive by wire system delivering power just like a modern car.

The fabrication process at Celeritech is as sophisticated as the design and development stages, working to the tight tolerances mapped out by the CAD design. It employs Celeritech’s own techniques and accurate CNC cutting via a special jig system, alongside TIG welding practices. Working with stainless steel and Inconel – a high tech material used in Formula One – the digital template comes to life, providing the precise number of degrees that the tubing sections need to twist relative to each other. Everything must be millimeter perfect. In fact, it’s checked with a laser system to support Celeritech’s own “perfect fit” guarantee. Heat protection comes in two forms, mechanically wrapped insulation and Ceracoat temperature treatments. The final product precisely replicates the virtual 3D design with true equal length becoming reality. Exactly what we wanted for KALMAR cars.

The completed KALMAR system is built from 304 grade stainless steel with a wall thickness of just 1.2mm (typically systems employ a less impressive 1.5mm wall), or as little as 0.7mm where Inconel is used, making it even lighter. Talking of weight, the Celeritech / KALMAR Automotive stainless steel system tips the scales at 27.7kgs (the original 993 system, as incomparable as it is in pretty much every way, weighs 38.6kgs). And the optional Inconel is even lighter still. Catalytic converters and a quartet of free-flowing silencers complete the recipe. Now, this feels like an opportune moment to mention sound! We’d be lying if we said we didn’t want an exhaust note to stir the soul, but this is another area where a compromise – this time between power and decibels – is often required. KALMAR Automotive demanded that its cars be homologated, but also nice to drive over longer distances, all without losing the soul of the Boxer six-cylinder, in this the team succeeded. Key factors such were the compression ratio and cam duration, with valve lift playing an equally important role in the eventual tune emitted from the rear. As space is tight on a Porsche 911 there was a need for an inventive approach in getting everything to fit. Our system’s true equal also lengths play an important role in producing the unique, melodic sound. Note that the sound from the system is well within the limits of road and track use, avoiding unwanted resonance with all its pulses arriving at the right intervals – largely created by its true equal length. It’s just like a perfectly tuned piano.

The team considers each aspect of the state-of-the-art CAD design before production. That means prior to fabrication, the KALMAR customer can completely tailor the system. A 3D render is shared with the customer so that any changes can be discussed and incorporated into the final form. The basis for the design of the KALMAR system was even more intensive. Built with a view to extracting optimum performance, the project called for a close collaboration between KALMAR, Celeritech and engine partner Lorrtec. Crucial aspects, such as the length and diameter of the primaries and secondaries were tested repeatedly, painstakingly checking the impact of each new adjustment to ensure it had the correct effect on the performance and power delivery of the engine. Here, Celeritech’s Tjabring Snel and Lorrtech’s Pierre Antoie Rampo harnessed their extensive experience of engine development and simulation work for professional motorsport applications, helping to strike what is a tricky balance between packaging, heat output, noise and desired performance outcome. You can see from our power graph that our goal was to create a drivable car with a wide power band and smooth idle, with the drive by wire system delivering power just like a modern car.

The fabrication process at Celeritech is as sophisticated as the design and development stages, working to the tight tolerances mapped out by the CAD design. It employs Celeritech’s own techniques and accurate CNC cutting via a special jig system, alongside TIG welding practices. Working with stainless steel and Inconel – a high tech material used in Formula One – the digital template comes to life, providing the precise number of degrees that the tubing sections need to twist relative to each other. Everything must be millimeter perfect. In fact, it’s checked with a laser system to support Celeritech’s own “perfect fit” guarantee. Heat protection comes in two forms, mechanically wrapped insulation and Ceracoat temperature treatments. The final product precisely replicates the virtual 3D design with true equal length becoming reality. Exactly what we wanted for KALMAR cars.

The completed KALMAR system is built from 304 grade stainless steel with a wall thickness of just 1.2mm (typically systems employ a less impressive 1.5mm wall), or as little as 0.7mm where Inconel is used, making it even lighter. Talking of weight, the Celeritech / KALMAR Automotive stainless steel system tips the scales at 27.7kgs (the original 993 system, as incomparable as it is in pretty much every way, weighs 38.6kgs). And the optional Inconel is even lighter still. Catalytic converters and a quartet of free-flowing silencers complete the recipe. Now, this feels like an opportune moment to mention sound! We’d be lying if we said we didn’t want an exhaust note to stir the soul, but this is another area where a compromise – this time between power and decibels – is often required. KALMAR Automotive demanded that its cars be homologated, but also nice to drive over longer distances, all without losing the soul of the Boxer six-cylinder, in this the team succeeded. Key factors such were the compression ratio and cam duration, with valve lift playing an equally important role in the eventual tune emitted from the rear. As space is tight on a Porsche 911 there was a need for an inventive approach in getting everything to fit. Our system’s true equal also lengths play an important role in producing the unique, melodic sound. Note that the sound from the system is well within the limits of road and track use, avoiding unwanted resonance with all its pulses arriving at the right intervals – largely created by its true equal length. It’s just like a perfectly tuned piano.

Finally, KALMAR customers can choose from three different tailpipe options for straight pipes, with a unique crossover infinity design being one of the highlights. The finishing touch is the Celeritech engraving, which marks out the KALMAR Automotive system as a beautiful, tight-fitting, high-performance exhaust system – something special created by passionate enthusiasts.

Finally, KALMAR customers can choose from three different tailpipe options for straight pipes, with a unique crossover infinity design being one of the highlights. The finishing touch is the Celeritech engraving, which marks out the KALMAR Automotive system as a beautiful, tight-fitting, high-performance exhaust system – something special created by passionate enthusiasts.